The dangers of stray voltage to gas field technicians

Gas Field Technicians face a significant and potentially deadly risk from stray voltage on pipes, meters and rectifiers. When an electrical system is grounded directly to the property’s pipework a hazardous situation arises in the event of an electrical fault, the Gas System becomes live.

Consequently, technicians working on a meter or rectifier are at risk of receiving a fatal electric shock. This is why emphasis should be placed on the critical importance of understanding and mitigating the dangers posed by stray voltage in the gas industry

How does your company check for dangerous stray voltages?

Many gas utility companies do not have a procedure in place for their Field Technicians that consistently checks for the presence of dangerous stray voltage. Making the procedure as safe, quick and easy as possible has proven more successful to ensure technicians follow it each and every time.

The safest, quickest and easiest way to check for stray voltage is by using a Non-Contact Voltage Detector. This device, about the size of a pen, is held close to the pipe, meter, or rectifier to detect dangerous voltage. If a dangerous voltage is present, the Voltage Detector will light up and warn the technician that voltage is present and to take caution. The technician can then follow procedures to reduce the risk of injury to themselves and their customers.

Why do the world’s leading utility companies trust Volt Stick?

Introducing Volt Stick, the pioneers of Non-Contact Voltage Detection technology. Since their groundbreakinginvention back in 1985, Volt Stick has remained the trusted expert in this field; continuously developing tools for the world’s leading utility companies. Their commitment to safety is evident being used in‘Safe to Touch’ procedures, making them an essential partner for ensuring electrical safety.

In 1998, a gas utility worker from TRANSCO (now National Grid) attended a residential property in response to a reported gas emergency. While attempting to gain access to the property’s gas meter, installed underneath the metal kitchen sink, the technician placed his hand on the sink and the emergency control valve. Tragically, a fatal electric shock was delivered due to a fault in the property’s electrical installation.

In 1998, a gas utility worker from TRANSCO (now National Grid) attended a residential property in response to a reported gas emergency. While attempting to gain access to the property’s gas meter, installed underneath the metal kitchen sink, the technician placed his hand on the sink and the emergency control valve. Tragically, a fatal electric shock was delivered due to a fault in the property’s electrical installation.

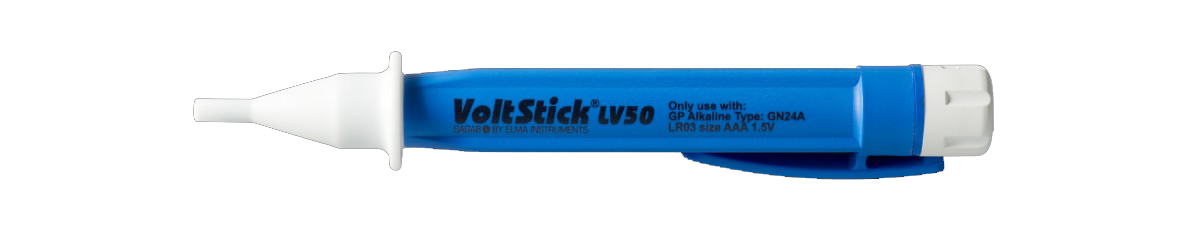

Volt Stick LV50

Increased sensitivity/ intrinsically safe

Around 25 years ago, the industry standard, ATEX / IECEx certified Volt Stick LV50 was developed, and it is still used by every National Grid gas engineer to ensure work environment safety.

The Volt Stick LV50 has also been in use by National Grid in the US for over 10 years, showing its reliability and effectiveness in preventing electric shock incidents. The development and widespread use of the Volt Stick LV50 has significantly improved safety measures for gas utility workers around the world, ensuring the prevention of tragic accidents like the one in 1998.

Can Volt Stick help with your ‘Safe to Touch’ procedure?

A leading US gas utility provider sought to replace their non-contact voltage detector with the intrinsically-safe Volt Stick LV50, which was seen as reliable and easy to use. However, the LV50 detected voltages of 50 Volts and above, while the Utility’s ‘Safe to Touch’ procedure required checking for voltages above 12 Volts.

After field trials, the new intrinsically-safe Volt Stick LV12 was developed in collaboration with the utility company to meet their specific requirements. The Volt Stick LV12 is now utilised by multiple gas utility

Why choose the Volt Stick LV50 or LV12 over cheaper alternatives?

You could be excused for looking at a Volt Stick LV50 or LV12 and thinking ‘there can’t be much difference between these and the cheaper alternatives’, but there are very good reasons that the LV50 and LV12 are sometimes more expensive!

When deploying your ‘Safe to Touch’ procedure you will decide on a ‘Safety Threshold’ and that might be 12 or50 volts. Unless you can be certain that the tools you use are capable of detecting voltages at or below that  threshold then your procedure is of no use and your team could be exposed to potentially lethal voltages.

threshold then your procedure is of no use and your team could be exposed to potentially lethal voltages.

There are certain standards that you expect a manufacturer to meet, and you would expect a product to do exactly what it says it should. But in reality, that is not always the case! Sometimes a 50-volt tester will not detect 50 volts!

Being intrinsically-safe doesn’t just mean that the LV50 & LV12 can be used in areas where hazardous gases may be present, it also signifies that they are designed and constructed to the highest standards. All Volt Stick Intrinsically Safe products are manufactured at an IECEx & ATEX certified facility, which also holds AS9100 Certification for producing components and products used throughout the aerospace and defence industries. Only the best components with the smallest tolerances can be used which ensures Volt Stick’s accuracy and reliability.

When a product is put forward for testing, every component, including batteries, must be listed and tested. If any of the product’s components or batteries were to change, due to EOL or long lead times, the product would require a lengthy recertification. Using quality components from trusted suppliers is more expensive but the future supply of those components is secured and guaranteed.

For many that use the LV50 and LV12, if for some reason they were to become unavailable it would seriously affect their procedures and ultimately their safety. For this reason, Volt Stick will often work closely with their customers and supply chain to ensure that they are holding enough stock to cover any unforeseen eventualities.

In conclusion, the choice between the Volt Stick LV50 or LV12 and cheaper alternatives is not just about the price. It’s about ensuring the safety, quality, reliability, accuracy and continuity of the product. The stringent testing, high manufacturing standards, and intrinsic safety certification make these products critical tools for ensuring safety in areas where hazardous gases may be present. The investment in these products goes beyond the initial cost, it guarantees the future supply and the safety of those who rely on these critical safety tools.

For specific requirements or advice on ‘Safe to Touch’ procedures, contact us

Email: info@voltstick.com | UK: +44 (0)115 9770075 | US: +1 315 314 3112

Read more: